When delivering complex commercial or industrial electrical projects, few components are more critical (and potentially problematic) than Cable Tray Systems. Contractors and project managers need an approach that is fast, safe, and compliant.

That’s where the Blitz Approach to Seismic Compliance comes in: a solution engineered to streamline cable tray installation, eliminate hot-work delays, and ensure seismic-rated performance straight out of the box.

This article highlights how Blitz Systems gives project managers and contractors the outcomes they need i.e. reduced labour, predictable timelines, and trustworthy, independently certified results.

You’ll discover how:

-

The Blitz approach solves the key issues with traditional methods

-

Blitz components combine for seamless installs

-

Real-world application eliminates inefficiency from the job site

By the end, you’ll learn why Blitz Systems is the go-to partner for faster, safer, and compliant duct, conduit, data, and cable tray support

Why Seismic Compliance Matters for Cable Tray Systems

For project leads across Australia, seismic compliance isn’t just another box to tick—it’s the difference between a safe installation and an expensive failure. Without seismic-ready systems, lives and infrastructure are at risk, making compliance a critical safety and legal requirement.

-

Safety First

If cable trays collapse during seismic activity, the risks are real: injured workers, compromised electrical systems, and damage to property. A robust cable tray system reduces these hazards, protecting lives and essential infrastructure. -

Financial Impact

Non-compliance can cause delays, on-site rework, and substantial repair bills. A seismic event can halt progress or worse, trigger legal repercussions and insurance complications. Investing in a compliant solution is far less expensive than dealing with project hold-ups or system failure. -

Regulatory Requirements

Within Australia, seismic bracing for suspended systems is not optional. Blitz Systems' solutions are independently certified according to ANSI/ASHRAE 171-2017 and designed to comply with AS 1170.4 for earthquake actions, giving project leads the assurance they need. That means approvals are straightforward, compliance is guaranteed, and you can focus on completing the job on schedule.

The Problem with Traditional Seismic Bracing Methods

Ask any contractor about seismic bracing, and they’ll tell you the same thing: the traditional way of doing it is a headache. What should be a straightforward installation turns into a drawn-out process with inefficiencies, hidden costs, and risks. Here’s why the old approach doesn’t hold up.

-

Complex and Slow

Traditional seismic bracing demands constant measuring, cutting, welding, and adjustments. Each step creates opportunities for error, and a single wrong cut means wasted material and lost time. Crews end up bogged down in rework and delays. The result: project timelines that slip and contractors left scrambling to make up lost days. -

Labor-Intensive

Because so much modification happens on-site, projects quickly become labour-intensive. Crews spend more time adjusting, cutting, and fitting than actually installing, which inflates labour hours. With wages climbing, every extra step eats into margins. Contractors are left paying more for a process that delivers lower efficiency. -

Safety Hazards

Traditional bracing often requires hot-works such as on-site welding, grinding, or cutting. This means additional supervision and a higher risk of serious accidents. Every spark adds another layer of liability for contractors and project managers, forcing them to navigate a process that compromises both safety and speed. -

Wasteful

On top of delays and risks, field cutting creates piles of scrap metal and excess waste. Crews spend additional time handling cleanup and disposal, adding costs that were never in the original budget. In a market where operationally lean and environmentally sustainable practices win contracts, waste-heavy methods put you at a clear disadvantage.

The Blitz Approach: A Smarter Way to Achieve Seismic Compliance

Traditional bracing slows projects, raises costs, and adds risks. Contractors need a smarter system that streamlines seismic compliance without compromise. That’s where the Blitz approach comes in, which is engineered for speed, safety, and reliability. With modular solutions, Blitz replaces outdated practices to deliver predictable timelines and reduced labour. Let’s take a closer look.

-

Faster

Blitz Systems delivers cable tray systems through modular, pre-engineered components, meaning no measuring, cutting, or welding on-site. Crews simply assemble parts that are designed to fit the first time. The result: installations that are up to 70% faster compared to conventional methods. Manuals make the process consistent across teams, so contractors can “click and go.” That speed keeps projects on schedule and frees up labour. -

Safer

Hot-works such as welding and grinding are some of the most hazardous tasks on-site. The Blitz approach eliminates them entirely. By relying on pre-engineered, bolt-together solutions, contractors avoid fire risks, reduce accidents, and remove the need for expensive permits and supervision. This ensures a cleaner, safer job site with less paperwork and fewer disruptions. -

Cost-Effective

Speed and safety both contribute directly to the bottom line. With Blitz, faster installs mean fewer labour hours and lower crew costs. Less waste on-site means less money spent on materials and disposal. And because the system is predictable and repeatable, contractors avoid rework and downtime. Those savings add up quickly across large projects, helping contractors keep budgets under control. -

Guaranteed Compliance

Compliance is non-negotiable, and Blitz takes eliminates the guesswork. Every product is tested and certified to meet seismic standards such as ANSI/ASHRAE 171-2017 and AS 1170.4. That means inspectors can sign off with confidence, and contractors can move forward without delays from failed checks or design revisions.

Key Products in the Blitz Seismic Solution

Building seismic-compliant Cable Tray Systems doesn’t have to mean complexity. Blitz provides a complete solution with modular supports and seismic bracing systems that integrate seamlessly, eliminate hot works, and guarantee performance under load.

-

STUDBITE Cable Tray Trapeze Supports

A modular, install-ready trapeze support system that simplifies suspended tray setups. These supports are independently certified for both fire and seismic compliance under AS 1170.4 and ANSI/ASHRAE 171-2017, offering high load capacity and quick, hot-work-free installation. -

STUDBITE Fire-Rated Trapeze Support

An enhanced version of STUDBITE designed for demanding environments, this support not only provides seismic compliance but also delivers up to 2-hour fire resistance (WS5X, 1050 °C). It supports trays up to 600 mm wide and carries heavy loads, offering double-duty protection in one component. -

STUDBITE Multi-Fix Bracket

Part of the STUDBITE family, it enables secure, adjustable fixation of seismic bracing and trays. It supports flexible configurations and helps create robust, code-compliant assemblies tailored for specific layouts. -

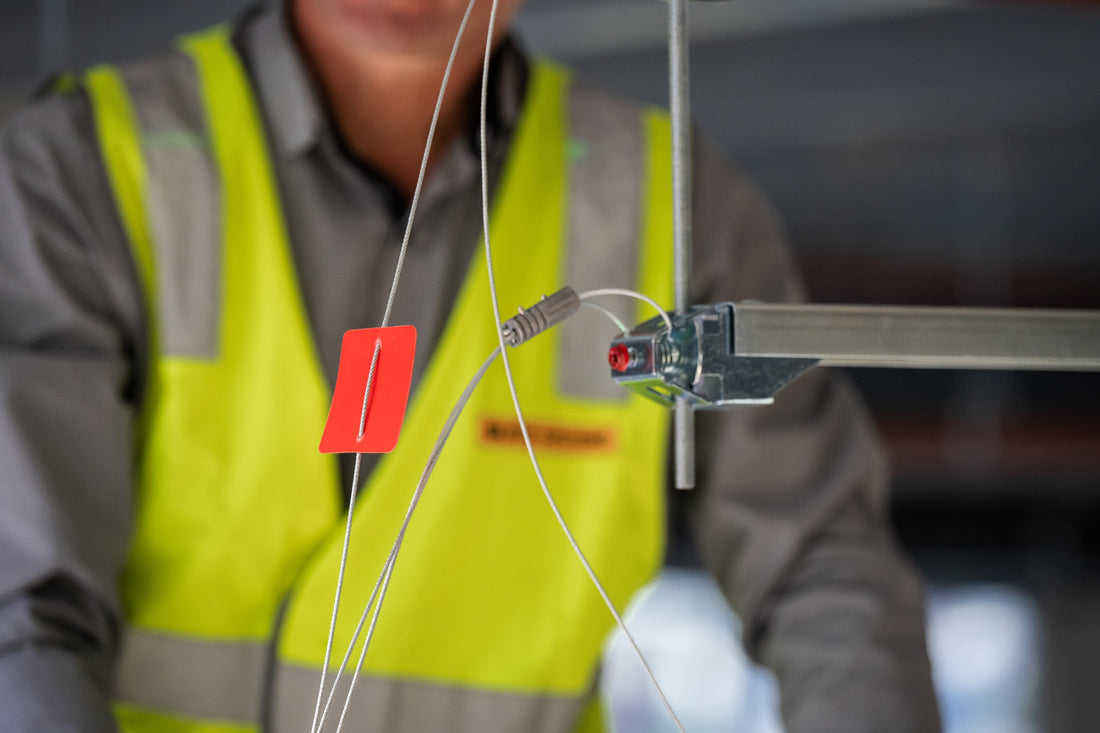

BLITZCLIP Seismic Wire Restraint System & Kits

A hot-work-free wire bracing system with grippers and pre-engineered steel wire, ready to install, even on damaged thread-on rods. The system meets seismic standards and eliminates the need for rods, channels, or welding in typical bracing setups. -

BLITZCLIP Seismic Wire Kit (2.0 mm)

A packaged solution offering wire lengths (1–5 m) with specified Safe Working Loads (SWL) for standard or heavy-duty adaptors. It simplifies sourcing and ensures users have ready-to-install seismic restraints tailored to their load requirements. -

BLITZCLIP + Wire Accessories

Includes gripper-only buckets and combined gripper and wire packages suitable for fast, clean seismic bracing installation. These accessories ensure installers have the right hardware on hand for any on-site scenario.

Faster Installs, Lower Costs: Fredon Vic Electrical’s Experience with Blitz Systems

BEFORE: Slow, Risky, and Wasteful

For Fredon Vic Electrical, large-scale, multi-story fit-outs often meant battling the inefficiencies of traditional cable tray installations. On-site cutting, bulky materials, and constant adjustments slowed progress and drove up labor costs. The process also generated excess scrap, adding safety risks and complicating clean-up. Managing deliveries across multiple floors only compounded the problem, stretching timelines and straining budgets.

AFTER: Time Saved, Costs Cut, Risks Reduced

That changed when they partnered with Blitz Systems during a high-end, multi-story fit-out project. By leveraging Blitz’s Quick Install Cable Tray and Basket Support Solutions, the team was able to:

-

Cut installation times significantly: Pre-engineered supports eliminated the need for on-site cutting, reducing error and speeding up assembly.

-

Reduce waste and risks: With fewer adjustments and no offcuts, the site stayed cleaner and safer.

-

Streamline logistics: Blitz offered separable deliveries broken down by floor, meaning materials were available exactly where and when they were needed, preventing bottlenecks and confusion.

-

Lower labor costs: The efficiencies translated into a leaner crew requirement, directly impacting the project’s bottom line.

Construction Manager, Gerard Higgins, summarized the impact: “By utilising their innovative systems, we reduced our installation times and minimised the resources required compared to traditional methods. The most significant cost savings were realised through labour reductions, which had a profound impact on our overall project budget.”

CONCLUSION

When it comes to seismic-rated Cable Tray Systems, there’s a smarter, safer, and faster path forward. The Blitz approach eliminates delays from on-site cutting or hot-weld work, lowers cost through reduced labour and waste, and ensures compliance you can count on.

Fast-Track Your Project With Built-In Compliance. Explore Blitz solutions on our website or reach out to a regional expert for an obligation-free consultation.

FAQs

Q: What specific standards do Blitz Systems' products comply with?

They’re independently certified to ANSI/ASHRAE 171-2017 and fully comply with AS 1170.4 for seismic actions, plus fire-rated per AS/NZS 3013:2005.

Q: How much faster is installation with the Blitz approach compared to traditional methods?

Installation is typically 50-70% faster, thanks to modular, pre-engineered components and reduced assembly time.

Q: Are the products suitable for both commercial and industrial projects?

Absolutely. They’re designed for use in commercial electrical, data, HVAC, manufacturing, and industrial environments.

Q: Can Blitz Systems' products be used with other cable tray brands?

Yes, Blitz systems integrate with standard cable tray systems and accessories, working alongside existing infrastructure while delivering improved speed and safety.