Introduction: Why Cable Tray Compliance Matters

Cable trays play a crucial role in modern electrical installations, providing essential support and organisation for cable wiring systems in commercial, industrial, and infrastructure projects. Selecting the right cable tray sizes ensures that installations are safe, efficient, and compliant with Australian electrical standards. Failing to meet these regulations can lead to operational inefficiencies, safety hazards, and legal consequences.

Compliance with Australian electrical standards is not just a formality; it is a fundamental requirement that ensures electrical systems are installed to withstand environmental factors, mechanical stress, and load-bearing expectations. By choosing correctly sized and compliant cable trays, electrical professionals can prevent overheating, mechanical failures, and fire hazards. Blitz Systems is committed to delivering high-quality, standards-compliant cable tray solutions to meet industry needs across Australia.

Understanding Australian Standards for Cable Trays

Key Regulations

Several Australian Standards regulate cable tray systems to ensure safety and reliability. The most relevant include:

-

AS/NZS 3000 (Wiring Rules): Governs electrical installations, ensuring that wiring support systems, including cable trays, adhere to safety and performance criteria.

-

AS/NZS 3013 (Fire Rating of Electrical Equipment): Specifies fire resistance requirements for electrical support systems, including cable trays used in fire-rated installations.

-

AS/NZS 1170 (Structural Design Actions): Outlines load-bearing requirements for structures, including cable tray support systems.

-

AS/NZS 2053 (Conduits and Fittings for Electrical Installations): Addresses compatibility between cable trays and other electrical components.

Blitz Systems designs and manufactures cable trays that comply with these stringent regulations, ensuring that customers receive reliable, high-performance products.

Risks of Using Non-Compliant Cable Trays

Non-compliant cable trays pose significant risks, including:

-

Increased fire hazards due to inadequate spacing and ventilation.

-

Structural failures from excessive load-bearing stress.

-

Legal liabilities arising from failing to meet national safety codes.

-

Increased maintenance costs due to corrosion or mechanical failures.

By choosing compliant products from Blitz Systems, businesses can mitigate these risks and ensure long-term reliability and safety.

How Cable Tray Size Impacts Compliance & Safety

Choosing the Correct Tray Size

Selecting the right cable tray size involves considering multiple factors, including:

-

Tray Width: Ensuring sufficient space for cable volume and airflow.

-

Tray Depth: Providing appropriate separation between cables to prevent overheating.

-

Load-Bearing Capacity: Supporting the weight of cables without sagging or failure.

-

Material Choice: Options include galvanised steel, aluminium, and stainless steel, each with unique benefits based on environmental conditions and compliance needs.

-

Environmental Considerations: Outdoor, marine, and high-corrosion areas require specific materials and coatings.

Consequences of Using Incorrectly Sized Cable Trays

Using undersized cable trays can result in:

-

Overcrowding, leading to poor ventilation and increased fire risks.

-

Structural instability due to excessive weight loads.

-

Compliance violations that can lead to project delays and costly rework.

-

Increased wear and tear on cables due to improper spacing and pressure.

Additionally, material selection plays a role in compliance. Blitz Systems offers cable trays in galvanised steel, aluminium, and stainless steel, ensuring durability and suitability for different environmental conditions.

Best Practices for Cable Tray Installation

To ensure compliance and safety, follow these best practices when installing cable trays:

-

Ensure Adequate Spacing: Avoid overcrowding by allowing sufficient room for cables to be placed without excessive bending or compression.

-

Proper Cable Tray Support: Follow AS/NZS guidelines for support placement to maintain structural integrity and prevent sagging.

-

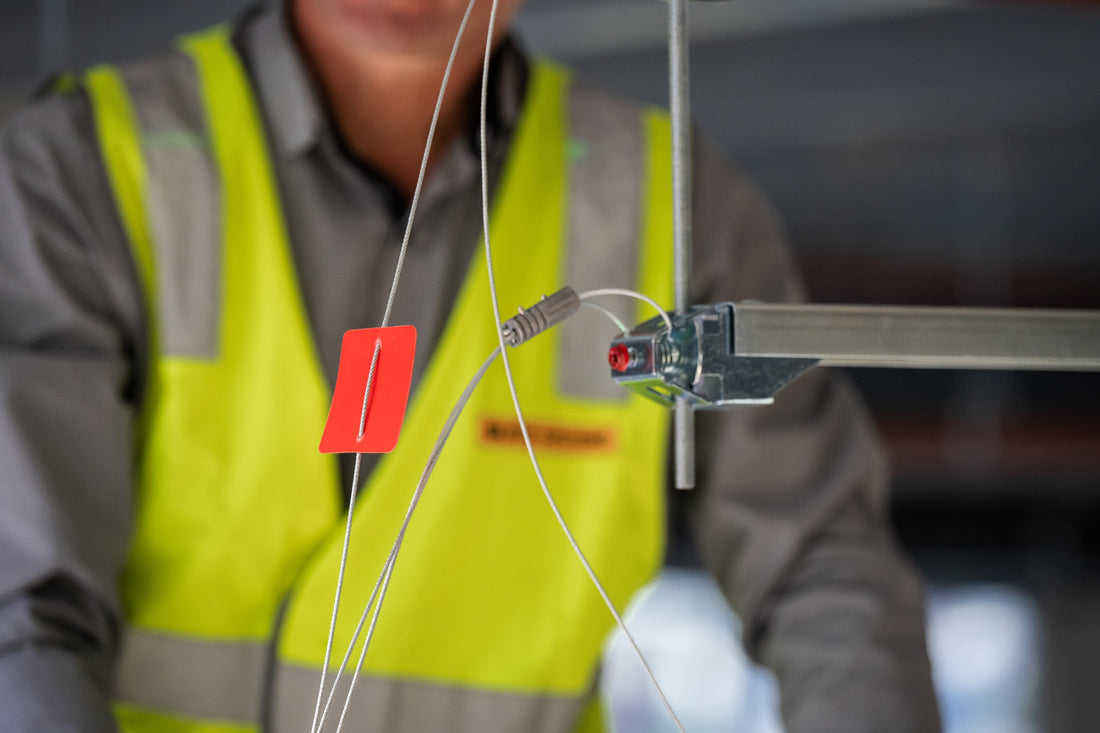

Correct Fasteners and Fixings: Use approved hardware to secure trays in place and prevent movement over time.

-

Regular Inspections: Conduct periodic maintenance checks to identify signs of corrosion, overloading, or mechanical wear.

-

Compliance Documentation: Maintain records of tray specifications, load ratings, and installation methods for compliance verification.

Common Compliance Mistakes & How to Avoid Them

Mistake #1: Choosing the Wrong Size Based on Cost Instead of Compliance

Some businesses opt for smaller trays to save costs, but undersizing can lead to compliance failures and increased long-term expenses. Solution: Work with Blitz Systems to select a properly sized, compliant cable tray.

Mistake #2: Ignoring Load Capacity Requirements

Failing to consider load-bearing requirements can lead to cable tray failures. Solution: Always verify load ratings and select trays designed for the intended cable weight.

Mistake #3: Not Considering Environmental Factors

Environmental conditions affect cable tray longevity. Outdoor installations require corrosion-resistant materials. Solution: Blitz Systems provides durable materials suited for various conditions.

Mistake #4: Improper Support Spacing

Inadequate spacing between cable tray supports can cause sagging or instability. Solution: Follow AS/NZS guidelines for support placement to maintain structural integrity.

Mistake #5: Overloading Cable Trays

Exceeding the weight capacity of a tray can lead to warping or failure. Solution: Use properly rated trays and distribute cable weight evenly.

Mistake #6: Failing to Plan for Future Expansion

A common oversight is installing cable trays without considering future cable additions. Solution: Choose a tray size with expansion capacity to prevent reinstallation costs.

How Blitz Systems Ensures High-Quality, Compliant Cable Trays

Blitz Systems is a trusted provider of cable tray solutions that meet and exceed Australian compliance requirements. Key benefits include:

-

Commitment to Compliance: Every product is rigorously tested to meet AS/NZS standards.

-

Extensive Range of Sizes: Custom sizing options ensure suitability for any project.

-

Expert Consultation: Professional advice to help businesses choose the right cable tray.

-

Fast Shipping: Efficient delivery across Australia for time-sensitive projects.

-

Durability and Performance: High-quality materials engineered for longevity and safety.

-

Comprehensive Accessories: Offering fittings, supports, and fasteners to complete any installation.

The Smart Choice for Compliance & Efficiency

Selecting the correct cable tray size is essential for safety, compliance, and operational efficiency. Non-compliance can result in project delays, financial penalties, and safety risks. By choosing Blitz Systems, professionals gain access to high-quality, standards-compliant products backed by expert guidance and reliable service.

Blitz Systems ensures that every cable tray meets rigorous Australian standards, providing businesses with peace of mind and long-term performance. Whether you need custom sizing, corrosion-resistant materials, or expert advice, Blitz Systems has the solution.

Contact Blitz Systems

Contact Blitz Systems today for expert advice and premium cable trays that meet Australian standards!

Contact Blitz