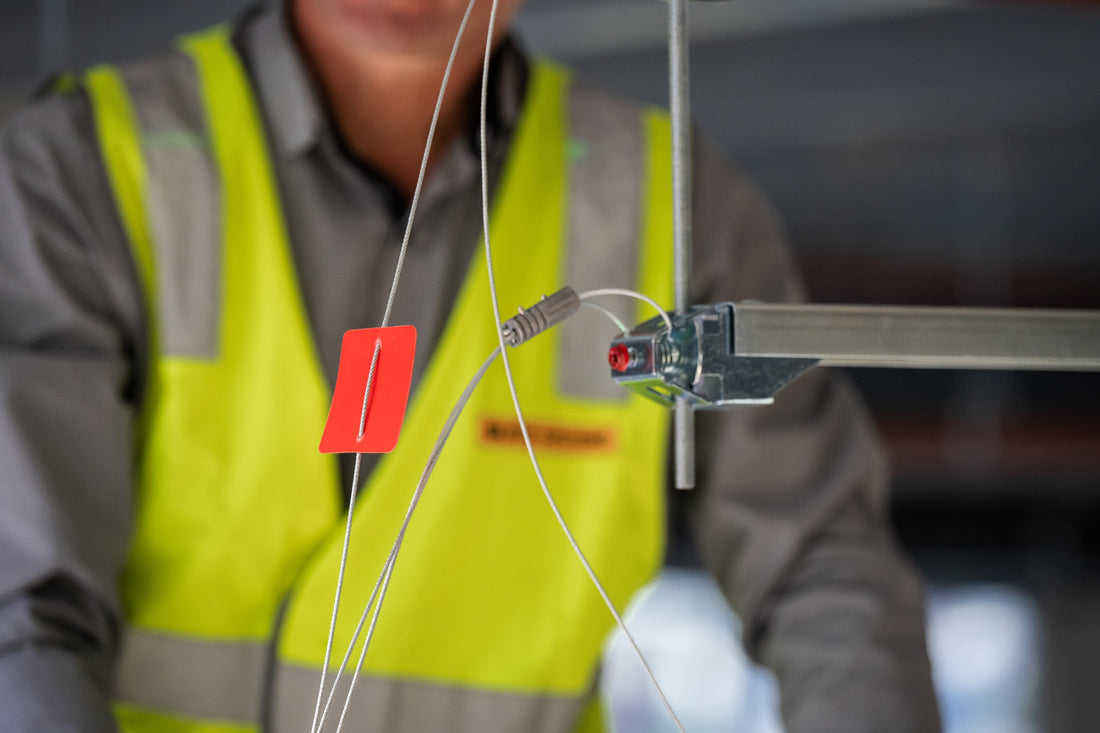

In the world of mechanical, HVAC, and industrial electrical contracting, ensuring that your projects meet the highest standards of safety, efficiency, and compliance is critical. At Blitz Systems, we understand the challenges that come with securing suspended non-structural equipment, especially in all areas where seismic restraint is required. That's why we've developed the BLITZCLIP Seismic Wire Restraint System - a cutting-edge solution designed to protect your installations from the potentially devastating effects of earthquakes.

The Blitz Systems Advantage

Blitz Systems has built a reputation for delivering innovative, high-quality products that save time, reduce costs, and simplify installation processes. Our BLITZCLIP Seismic Wire Restraint System is no exception. This system is not just about seismic compliance; it’s about bringing a new level of efficiency and flexibility to your projects, allowing you to focus on what you do best—delivering exceptional results.

Fast Installation with Minimal Effort

Time is money, especially in the fast-paced world of construction and industrial installations. The BLITZCLIP Seismic Wire Restraint System is engineered with this in mind, offering a host of features that drastically reduce installation time and labour costs:

No Cutting or Deburring

Traditional seismic bracing systems often require extensive preparation, including cutting and deburring of materials, which adds to the installation time and complexity. With BLITZCLIP, these steps are completely eliminated. The system arrives ready to install, allowing your team to get to work immediately.

No Spray Painting to Seal Cut Ends

Sealing cut ends is a time-consuming process that also introduces the risk of environmental hazards and inconsistent finishes. The BLITZCLIP system is designed to avoid the need for cutting altogether, meaning there’s no need for spray painting or additional sealing, streamlining your workflow and maintaining a clean, professional installation.

Minimal Parts

The system’s design is incredibly efficient, requiring only a few components to achieve secure, compliant installations. By eliminating unnecessary parts like nuts and washers, BLITZCLIP reduces the potential for errors and simplifies the installation process.

Flexibility and Safety at the Core

One of the standout features of the BLITZCLIP Seismic Wire Restraint System is its unparalleled flexibility. This system is designed to adapt to the unique demands of your project, offering solutions that are both practical and safe:

Installation on Damaged Thread-On Rods

In many cases, the condition of existing infrastructure can pose challenges for installation. BLITZCLIP is engineered to be installed even on damaged thread-on rods, reducing the need for costly replacements and keeping your project on schedule.

No Need for Allocated Hot Works Areas or Permits

Hot works, such as welding and cutting, require special safety measures, permits, and designated areas, all of which can slow down a project. With BLITZCLIP, these concerns are a thing of the past. The system can be installed without any hot works, ensuring a faster, safer, and more straightforward installation process.

No Need for Strut/Channel for Trays Up to 225mm

For installations involving trays up to 225mm, the need for additional strut or channel is completely eliminated, further reducing material costs, installation time, and the logistical challenges associated with managing and storing large quantities of strut on-site.

A Comprehensive Approach to Seismic Compliance

Seismic compliance is not just about meeting regulations; it’s about protecting lives and ensuring the integrity of your projects. The BLITZCLIP Seismic Wire Restraint System meets the stringent requirements of ANSI/ASHRAE 171-2017 and AS1170.4 for earthquake actions in Australia. Here’s how our process works:

-

Project Review: We start by reviewing the project drawings provided by the client. This initial step allows us to understand the specific requirements and constraints of the project.

-

Seismic Compliance Assessment: Based on the project details, we assess whether seismic compliance is necessary. If it is, we move forward with a tailored approach that meets all relevant standards.

-

Estimate and Design Proposal: We provide an estimate that includes all necessary seismic components along with a fee for seismic design and sign-off. This transparent approach ensures there are no surprises down the line.

-

Seismic Design Creation: Once the estimate is approved and a purchase order is issued, our expert seismic engineers get to work. They create a detailed seismic design that is tailored to the specific needs of the project.

- Final Design and Quote: After the seismic design is completed, we send the revised design back to the client, along with a final quote that reflects the correct quantities and any adjustments made during the design process.

This streamlined procedure not only simplifies the compliance process for our clients but also ensures that every detail is handled with precision and care. By providing both the seismic design and the restraint kits, Blitz Systems offers a comprehensive solution that takes the guesswork out of seismic compliance.

The Bottom Line: Flexibility, Efficiency, and Safety

At Blitz Systems, we believe that flexibility is key to successful project management. The BLITZCLIP Seismic Wire Restraint System is designed to adapt to your needs, offering a faster, safer, and more efficient way to achieve seismic compliance. Whether you’re managing a large-scale industrial installation or a more modest project, BLITZCLIP provides the tools you need to get the job done right.

Take the Next Step

Ensure your project is secure, compliant, and completed on time with the BLITZCLIP Seismic Wire Restraint System. Visit our website to learn more about our innovative solutions and make an inquiry today.