Top Installation Tips for Cable Trays by Blitz Systems: Insights for Australian Electricians

Proper cable tray installation is essential in managing and protecting electrical cables in various settings, from industrial sites to commercial buildings. For Australian electricians, understanding the best practices for installing cable trays not only ensures safety but also enhances the efficiency and longevity of the entire electrical system. This comprehensive guide by Blitz Systems provides top tips for installing cable trays, positioning Blitz as your trusted partner in cable management solutions across Australia.

Understanding Cable Trays

Cable trays are crucial components in electrical installations, serving as pathways that support and protect cables. They offer several advantages, including improved organisation, enhanced safety, and easier maintenance compared to other cable management methods like conduit systems.

Types of Cable Trays

Understanding the different types of cable trays is the first step in selecting the right solution for your project:

Ladder Cable Trays: These trays are ideal for heavy-duty applications where high load capacity and excellent ventilation are required. They are typically used in industrial settings and can handle large bundles of cables. The open design allows heat to dissipate, reducing the risk of overheating.

Perforated Cable Trays: With a perforated base and sides, these trays offer partial cable protection and allow for some airflow. They are suitable for general-purpose installations where cable protection is necessary, but ventilation is also a concern.

Solid Bottom Cable Trays: These trays provide maximum protection for cables, shielding them from dust, dirt, and other environmental factors. They are best used in situations where cables need to be fully enclosed, such as in areas with high contamination risks.

Wire Mesh Cable Trays: Lightweight and easy to install, wire mesh trays are perfect for low-voltage applications and short cable runs. They offer flexibility and can be easily adapted to fit various layouts and configurations.

Each type of tray has its specific applications, and the choice depends on factors such as the environment, cable type, load capacity, and installation requirements.

Benefits of Using Cable Trays

Cable trays offer numerous benefits, making them a preferred choice for cable management:

Improved Organisation: Cable trays provide a structured pathway for cables, reducing clutter and simplifying cable management.

Enhanced Safety: By keeping cables organised and off the floor, cable trays minimise the risk of tripping hazards and potential cable damage, contributing to overall site safety.

Ease of Maintenance: With cable trays, it's easier to access and modify cable installations, reducing downtime and maintenance costs.

Scalability: Cable trays can be easily adjusted or expanded, making them a flexible solution for growing installations.

Cost-Effectiveness: Compared to conduit systems, cable trays are often more economical, both in terms of material and installation costs.

Pre-Installation Preparation

Successful cable tray installation starts long before the first tray is mounted. Proper preparation ensures that the installation process runs smoothly and that the final system meets all safety and performance standards.

Site Assessment

A thorough site assessment is critical. Begin by evaluating the installation environment to determine factors such as:

Load Capacity: Calculate the weight of the cables and ensure that the selected tray type can handle the load without sagging or bending.

Environmental Conditions: Consider factors like temperature, humidity, and exposure to chemicals or corrosive elements. For example, in highly corrosive environments, a stainless steel or fibreglass cable tray might be necessary.

Access and Clearance: Ensure there is adequate space for installation and future maintenance. Check for any obstructions that might impede the installation process.

Planning and Design

Effective planning and design are key to a successful cable tray installation. Here are some tips to ensure your design is robust:

Create Detailed Layouts: Use schematics or digital design tools to map out the tray system, including all routes, bends, and junctions. A well-thought-out layout helps avoid costly mistakes during installation.

Compliance with Standards: Ensure that your design complies with relevant Australian standards, such as AS/NZS 3000 (the Wiring Rules). This not only ensures safety but also prevents issues during inspections.

Allow for Future Expansion: Design with scalability in mind. Leave room for additional trays or upgrades to accommodate future cable additions.

Installation Tips from Blitz Systems

Blitz Systems offers a range of high-quality cable tray solutions designed to meet the diverse needs of Australian electricians. Here are some expert tips to help you achieve the best results in your cable tray installations:

Safety First

Safety should always be your top priority. Follow these safety guidelines during installation:

Wear Appropriate PPE: Always wear safety glasses, gloves, and other protective gear to safeguard against potential injuries.

Use Insulated Tools: To prevent electrical shocks, use insulated tools, especially when working near live circuits.

Isolate Power Sources: Ensure that all power sources are de-energised before starting work. Use lockout/tagout procedures where applicable to prevent accidental re-energisation.

Proper Support and Spacing

Support and spacing are critical for maintaining the structural integrity of the cable tray system:

Install Supports at Regular Intervals: Follow manufacturer guidelines for support spacing. For most ladder trays, supports should be spaced between 1.5 and 3 metres apart, depending on the load.

Use Appropriate Brackets and Fasteners: Secure trays with the correct brackets, hangers, and anchors. Avoid using makeshift supports, as they can compromise the stability of the installation.

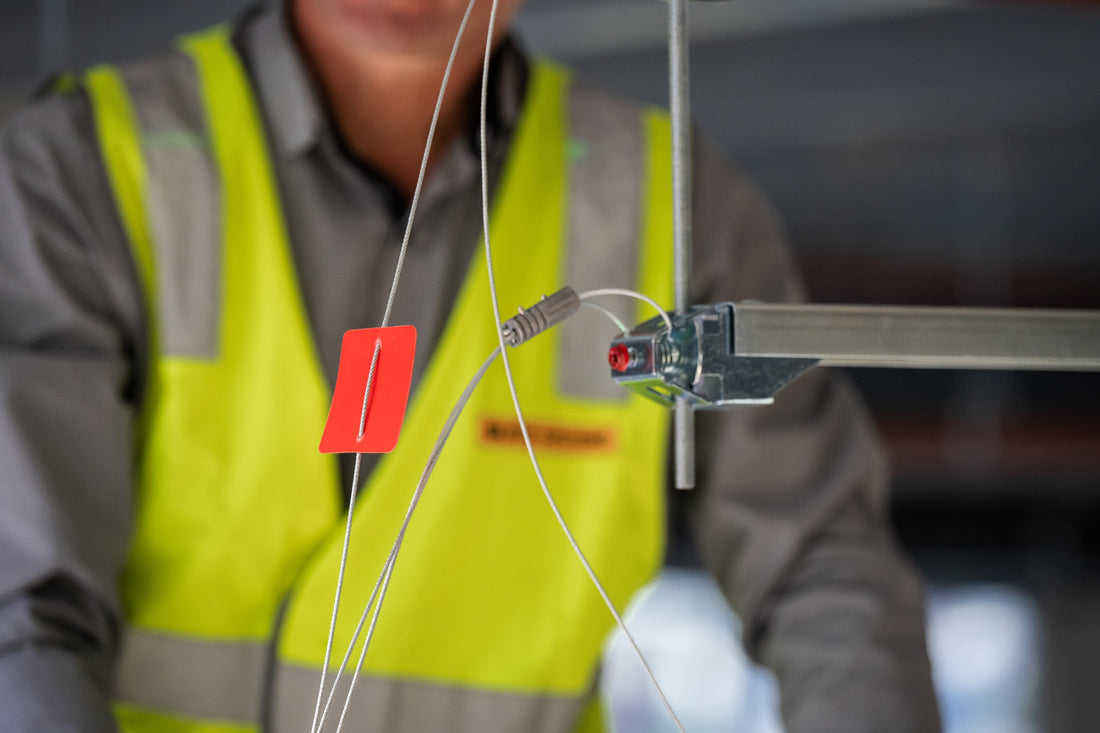

Securing Cable Trays

Properly securing cable trays ensures that they remain stable and perform as intended:

Mounting: Use the appropriate mounting hardware for the surface type—whether it's concrete, steel, or wood. Ensure that mounts are rated for the load and conditions of your installation.

Alignment: Make sure that tray sections are aligned correctly to avoid gaps or misalignment that could cause cable damage or impair system performance.

Cable Tray Connections

Connecting tray sections securely is vital for a robust installation:

Use Manufacturer-Recommended Fittings: Use the correct couplings, splice plates, and bolts to join tray sections. This not only ensures a secure connection but also maintains the tray's load-bearing capacity.

Handle Bends and Turns with Care: Avoid sharp bends that can strain cables. Use pre-formed bends and elbows to maintain a smooth path for cables, reducing the risk of damage.

Grounding and Bonding

Proper grounding and bonding are crucial for safety and compliance:

Ensure Electrical Continuity: Use grounding kits to bond tray sections together. This helps prevent potential differences that could lead to shock hazards.

Follow Standards: Comply with Australian regulations for grounding and bonding to ensure the safety of the installation.

Load Distribution

Even load distribution is key to preventing cable tray failure:

Distribute Cables Evenly: Avoid overloading specific sections of the tray. Distribute cables evenly across the width of the tray and use dividers to keep different cable types separated if necessary.

Check Load Ratings: Always check the tray’s load rating and ensure that your installation does not exceed these limits.

Post-Installation Checks

Once installation is complete, it’s essential to perform thorough checks to ensure the system is safe and ready for operation.

Inspection and Testing

Visual Inspection: Check for any signs of damage, misalignment, or loose fittings. Make sure all connections are secure and that the trays are properly supported.

Load Testing: If required, perform load testing to ensure that the tray can handle the expected weight of cables without bending or sagging.

Compliance Check: Verify that the installation meets all relevant standards and regulations, including proper grounding and bonding.

Maintenance Tips

Regular maintenance is key to the longevity and reliability of your cable tray system:

Schedule Regular Inspections: Periodically inspect the cable trays for signs of wear, corrosion, or damage. Look for loose fittings, sagging sections, or accumulated debris that could obstruct cables.

Address Issues Promptly: If any issues are detected, address them immediately to prevent further damage or safety hazards.

Keep Trays Clear: Ensure that trays remain clear of unnecessary items or debris that could impede airflow or cause cable damage.

Blitz Systems: Your Partner in Cable Management

Blitz Systems is committed to providing Australian electricians with high-quality cable tray solutions designed to meet the toughest demands. Here's why Blitz Systems should be your go-to provider for cable management:

Why Choose Blitz Systems?

Expertise and Innovation: With years of experience in the industry, Blitz Systems continuously innovates to bring electricians the best in cable management solutions. From design to manufacturing, Blitz Systems ensures that every product meets the highest standards of quality and performance.

Comprehensive Product Range: Whether you need ladder trays for heavy-duty installations or wire mesh trays for light-duty applications, Blitz Systems has a solution tailored to your needs.

Customer-Centric Approach: Blitz Systems values customer feedback and uses it to refine and improve their product offerings. They are dedicated to providing solutions that not only meet but exceed customer expectations.

Blitz Systems’ Commitment to Quality

Quality is at the heart of everything Blitz Systems does. All products undergo rigorous testing to ensure they perform reliably in real-world conditions. By choosing Blitz Systems, you’re not just buying a product—you’re investing in a solution designed to stand the test of time.

Installing cable trays correctly is crucial for the safety, efficiency, and reliability of electrical systems. By following these tips and best practices, Australian electricians can enhance their skills and ensure top-notch installations.