Introduction

The backbone of any robust infrastructure project lies in its ability to effectively manage and protect the vital electrical systems that power our homes, businesses, and industries. At the heart of this management is the often-overlooked yet crucial component: the cable support system. These systems are integral to ensuring that electrical installations are not only safe and organised but also efficient and long-lasting.

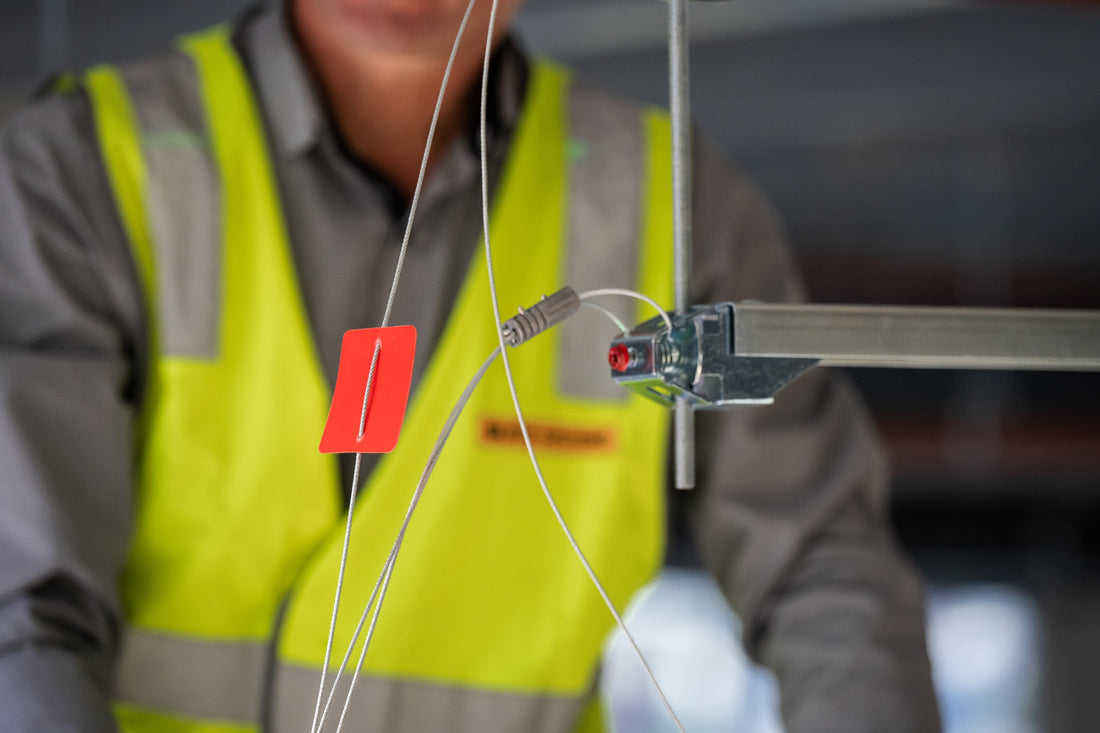

Cable support systems, which include cable trays, ladders, baskets, and raceways, play a pivotal role in maintaining the integrity of electrical wiring in various settings. Whether it’s a commercial building, industrial plant or a large-scale infrastructure project, the proper installation and maintenance of these systems are paramount.

What is Cable Support?

Cable support refers to the framework and methods used to manage, organise, and protect electrical cables within a building or infrastructure. These systems are designed to hold cables in place, preventing them from sagging, bending, or getting tangled, which could lead to damage or inefficiencies.

The primary purpose of cable support systems is to ensure that cables remain organised, accessible, and protected throughout their service life. This is particularly important in complex installations where numerous cables are required to power different systems or components. By using the appropriate cable support system, professionals can avoid common issues such as overheating, electromagnetic interference, and physical damage to cables.

Key Components of Cable Support Systems

Several key components make up a cable support system, each serving a unique function in supporting and organising cables:

Cable Trays

These are used to support insulated cables in a variety of settings, ranging from industrial to commercial environments. Cable trays come in several types, including solid bottom trays, which offer complete protection, ventilated trays that allow airflow to prevent overheating, and ladder-type trays designed for heavier cables.

Cable Ladders

Similar to cable trays, cable ladders provide support for cables, particularly in environments where robustness and durability are essential. They are especially useful for supporting large, heavy cables and offer the added benefit of air circulation around the cables.

Cable Baskets

These are ideal for supporting lighter cables and are often used in environments where flexibility and quick installation are priorities. Cable baskets allow for easy routing of cables and can be adjusted as needed without requiring significant structural changes.

Benefits of Cable Support Systems

The implementation of a well-designed cable support system offers a multitude of benefits, all of which contribute to the overall efficiency, safety, and longevity of an electrical installation.

Enhanced Safety and Organisation

A primary benefit of cable support systems is the enhanced safety they provide. By keeping cables neatly organised and securely fastened, the risk of accidents such as tripping, electrical fires, or interference with other systems is significantly reduced. Additionally, organised cables are easier to identify and manage, which is crucial in emergency situations where quick access is needed.

Improved Cable Lifespan and Performance

Cables that are properly supported are less likely to suffer from physical damage such as bending, sagging, or crushing. This not only extends the lifespan of the cables but also ensures that they perform optimally throughout their service life. Over time, this can lead to significant cost savings as the need for repairs or replacements is minimised.

Easier Maintenance and Troubleshooting

When cables are neatly arranged and easily accessible, maintenance becomes a straightforward task. Technicians can quickly identify and address issues without having to navigate through a tangled mess of wires. This not only reduces downtime but also ensures that any problems are resolved efficiently, keeping systems running smoothly.

Compliance with Industry Standards and Regulations

Many industries have strict regulations regarding the installation and maintenance of electrical systems. By implementing a proper cable support system, businesses can ensure that they remain compliant with these standards, avoiding potential fines, penalties, or delays in project completion.

Types of Cable Support Systems

There are several types of cable support systems available, each designed to meet the specific needs of different applications. Understanding the characteristics and advantages of each type is essential for selecting the right system for your project.

Cable Trays

-

Solid Bottom Trays: These trays offer complete protection for cables, making them ideal for environments where cables need to be shielded from dust, moisture, or physical damage. However, they may limit airflow, which could be a consideration in environments where heat dissipation is important.

-

Ventilated Trays: These trays have slots or perforations that allow air to circulate around the cables, preventing overheating. Ventilated trays are commonly used in environments where temperature control is a concern.

-

Ladder-Type Trays: Designed for heavy-duty applications, ladder-type trays provide strong support for large cables while allowing air to circulate freely. This type is often used in industrial settings where robustness and durability are essential.

Cable Ladders

Cable ladders are similar to ladder-type trays but are typically more robust, offering superior support for heavy cables. They are often used in industrial environments where large, heavy cables need to be supported over long distances.

Cable Baskets

Cable baskets are lightweight and easy to install, making them ideal for supporting lighter cables. They offer flexibility in routing and can be adjusted or reconfigured as needed without requiring major structural changes. Cable baskets are commonly used in environments where quick installation and adaptability are important.

Raceway Systems

Raceway systems are enclosed conduits that protect cables from environmental hazards such as dust, moisture, and physical damage. They provide a secure, tidy method for managing cables and are often used in settings where cables are exposed to potential risks. Raceways can be made from a variety of materials, including metal and plastic, depending on the specific needs of the installation.

Best Practices for Implementing Cable Support

To ensure the effectiveness of your cable support system, it’s essential to follow best practices during planning, design, and installation.

Planning and Design Considerations

Proper planning is crucial for determining the most effective cable support solution. This includes assessing the type and quantity of cables, the environment in which they will be installed, and the potential for future expansion. By considering these factors early in the design process, you can avoid common pitfalls and ensure that the system is both efficient and scalable.

Material Selection

The choice of materials for your cable support system is also important. Metal is often preferred for its durability and strength, particularly in industrial environments. However, plastic may be more suitable in environments where corrosion resistance and lightweight properties are desired. The specific environment and application will largely dictate the best material choice.

Installation Guidelines

Following manufacturer guidelines for installation is essential to ensure that the cable support system is secure and effective. This includes proper spacing between supports, ensuring that cables are properly fastened, and verifying that the system is installed level and aligned. Taking the time to install the system correctly will prevent issues down the line and ensure that the system performs as intended.

Ensuring Future Scalability and Flexibility

It’s important to design your cable support system with future growth in mind. This means selecting systems that can easily accommodate additional cables or upgrades without requiring significant rework. By planning for scalability, you can avoid costly modifications or downtime when it comes time to expand or upgrade your electrical systems.

Regular Maintenance and Inspections

Like any other component of an infrastructure project, cable support systems require regular maintenance and inspections to remain in good condition. This includes checking for signs of wear or damage, ensuring that cables remain securely fastened, and verifying that the system is functioning as intended. Regular maintenance not only extends the lifespan of the system but also helps prevent potential issues before they become serious problems.

Conclusion

Cable support systems are an integral part of any infrastructure project, playing a vital role in the safety, efficiency, and longevity of electrical installations. By following best practices and selecting the right system for your needs, you can ensure optimal performance and compliance with industry standards.

As infrastructure projects continue to evolve and grow in complexity, the importance of reliable cable support systems will only increase. Investing in a well-designed cable support system today will pay dividends in the form of improved safety, efficiency, and cost savings for years to come.