What is a Cable Tray?

Cable trays are structural supports designed to transmit loads from attached cables and wiring systems while providing protection for the cables. They are an assembly of cavities or channels made from various materials designed to securely support and provide physical protection for cables and electrical wiring systems in compliance with standards. Cables are safely guided through the tray and are arranged in an accessible manner to ensure the safety of its users and the equipment.

The types of cable trays include:

Ladder Tray

Used to support heavy-duty cables – especially those in the industrial field because of its strong and reliable nature.Trough Tray

This four-sided tray provides better protection for cables against outside elements making it a good choice for outdoors or rough environments.Channel Tray Solid bottom channel tray with continuous support for the cables, often used in telecommunication and data-centre applications.Wire Mesh Tray

Consisting of wire mesh, tends to be flexible and easy to install in a mainstream commercial building for light duty cabling support.

Why Cable Tray Support is Crucial

Cable tray support systems are important because they reduce unnecessary complications in electrical and communication networks. This ensures that networks are safe and not straining the connectivity from sagging cables. This can potentially lead to damage, hence reducing the risk and preventing this on top of ensuring ventilation to reduce heating issues. Some of the key problems caused by poorly executed systems or a lack of cable tray support systems altogether, include the following:

System Failures

Poor support mechanisms can lead to cables sagging and become damaged. This can result in the formation of an electrical fault. This can lead to system failure.Safety Hazards

Unsecured cables pose a risk of tripping, electrical shocks, and fire hazards.Challenges to Maintenance

Uncontrolled and unprepared cables to conduct inspections, maintenance or upgrades.

Types of Cable Tray Support Systems

There are various cable tray support systems, each offering unique benefits and suitable for different applications:

Ladder Support Systems

Known for their robustness, ladder support systems are ideal for heavy-duty applications where cables require strong, reliable support.

Benefits: High load capacity, ease of cable installation and maintenance.

Drawbacks: Limited protection against environmental elements.

Trough Support Systems

Providing a protective enclosure, trough systems are perfect for environments where cables need extra protection.

Benefits: Enhanced protection, suitable for outdoor and industrial settings.

Drawbacks: Heavier and more challenging to install compared to ladder systems.

Channel Support Systems

Offering continuous support, channel systems are excellent for sensitive cables that require stable and consistent support.

Benefits: Continuous support, easy to install in confined spaces.

Drawbacks: Limited load capacity compared to ladder systems.

Wire Mesh Support Systems

Lightweight and flexible, wire mesh systems are ideal for light-duty applications and areas with frequent changes in cable layout.

Benefits: Flexibility, ease of installation and modification.

Drawbacks: Lower load capacity and protection compared to other types.

Installation and Maintenance of Cable Tray Support

Firstly, it is essential to ensure that the different parts of the system are firmly fixed in position so that there is no unwanted movement in the cable tray. This principle applies to all parts of the system.

Firstly, it is essential to ensure that the different parts of the system are firmly fixed in position so that there is no unwanted movement in the cable tray. This principle applies to all parts of the system.

Secondly, workers must reduce undesired vibrations as much as possible when mounting and cleaning the cable-tuning system. While workers should always be careful, making extra effort to ensure no noise is generated is crucial when dealing with cables for several districts and residential estates.

Finally, when completing the work, workers should inspect the system to check for any damage. If the workers ever encounter difficulties, they should immediately alert the supervisor in order to provide assistance and resolve the situation as quickly as possible to reduce any interruption to the system.

In conclusion, as long as workers remember to manoeuvre carefully around the equipment and maintain a close eye on their work, they should be able to install the cable-tuning system successfully and ensure that cables remain intact and properly protected across districts and residential estates.

Plan the site by evaluating its environmental conditions and selecting the required cable tray along with the most suitable cable tray support system.

Planning: Design a comprehensive layout with a tray path, support mounts and cable management.

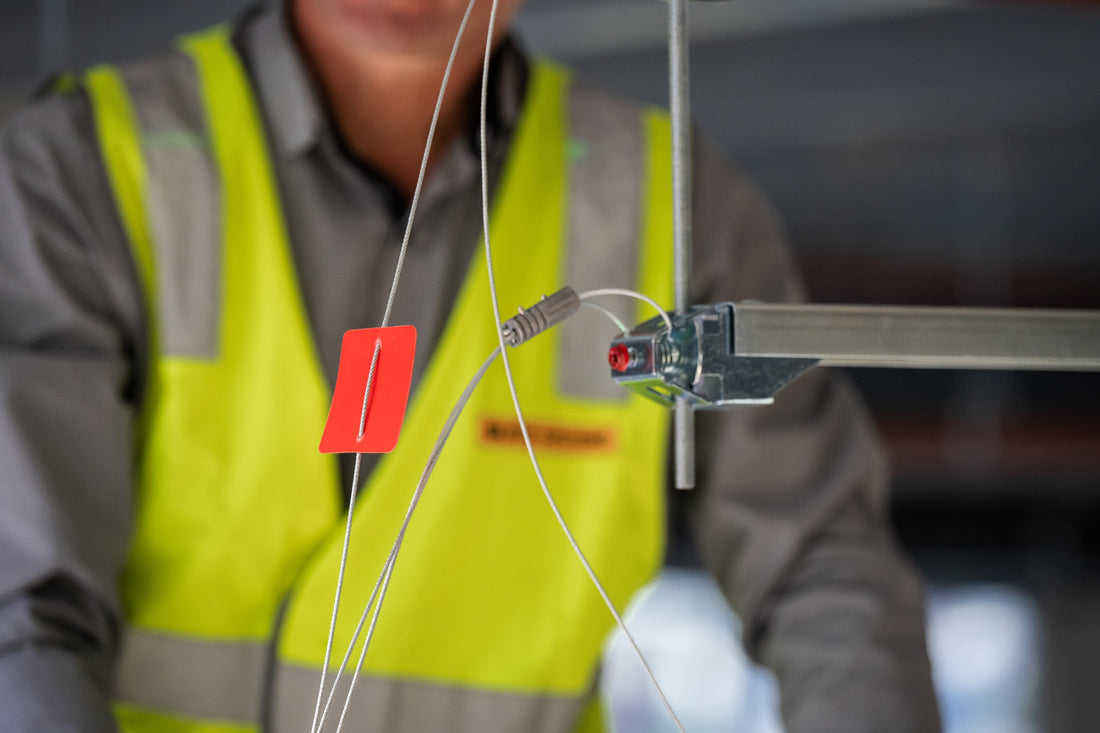

Mounting: Secure the support brackets and hangers at appropriate intervals to ensure stability.

Tray installation: Install the cable trays in accordance with the design drawing. Please ensure the cable trays are rightly positioned and fixed.

Cable Laying: Lay the cables into the trays working with industry accepted spacing and organisation.

Inspection: Check all components are installed and any cables are attached and supported appropriately.

Maintenance

Regular maintenance is essential to ensure the longevity and safety of cable tray support systems. Key maintenance practices include:

Routine Inspections: Regularly inspect the trays and supports for signs of wear, damage, or corrosion.

Cleaning: Keep the trays clean and free from debris to maintain proper ventilation and prevent overheating.

Tightening: Check and tighten all connections and fasteners to ensure stability.

Upgrades: Replace or upgrade components as needed to accommodate changes in cable load or environmental conditions.

Common Challenges and Solutions

Environmental Conditions

Problem: Exposure to weather conditions, chemicals and moisture could make cable tray support deteriorate due to corrosion and decomposition.

Overloading Loading a tray beyond its carrying capacity can cause it to sag and structurally fail.

Poor Installation Incorrect installation practices can compromise the effectiveness of the support system.

Solutions

Material Selection: Use corrosion-resistant materials such as stainless steel or aluminium for trays and supports in harsh environments.

Load Management: Ensure proper load distribution and adhere to the recommended load capacities during installation.

Training: Provide proper training to installation personnel to ensure adherence to industry standards and best practices.

Innovations in Cable Tray Support

Recent advancements in cable tray support systems have led to improved efficiency, safety, and ease of installation. Some notable innovations include:

Smart Cable Trays: Equipped with sensors and monitoring systems, smart cable trays provide real-time data on cable load, temperature, and integrity.

Modular Systems: Modular tray systems offer flexibility and ease of assembly, allowing for quick adjustments and expansions.

Composite Materials: The use of composite materials enhances the durability and corrosion resistance of cable trays, extending their lifespan in harsh environments. Without proper cable tray support, modern infrastructure would come crashing down. To improve workplace and consumer safety, overcome rugged geographic barriers, and futureproof all applications, it’s important to recognise the different types of cable tray systems, how to install and maintain them, and the technologies driving the industry forward.